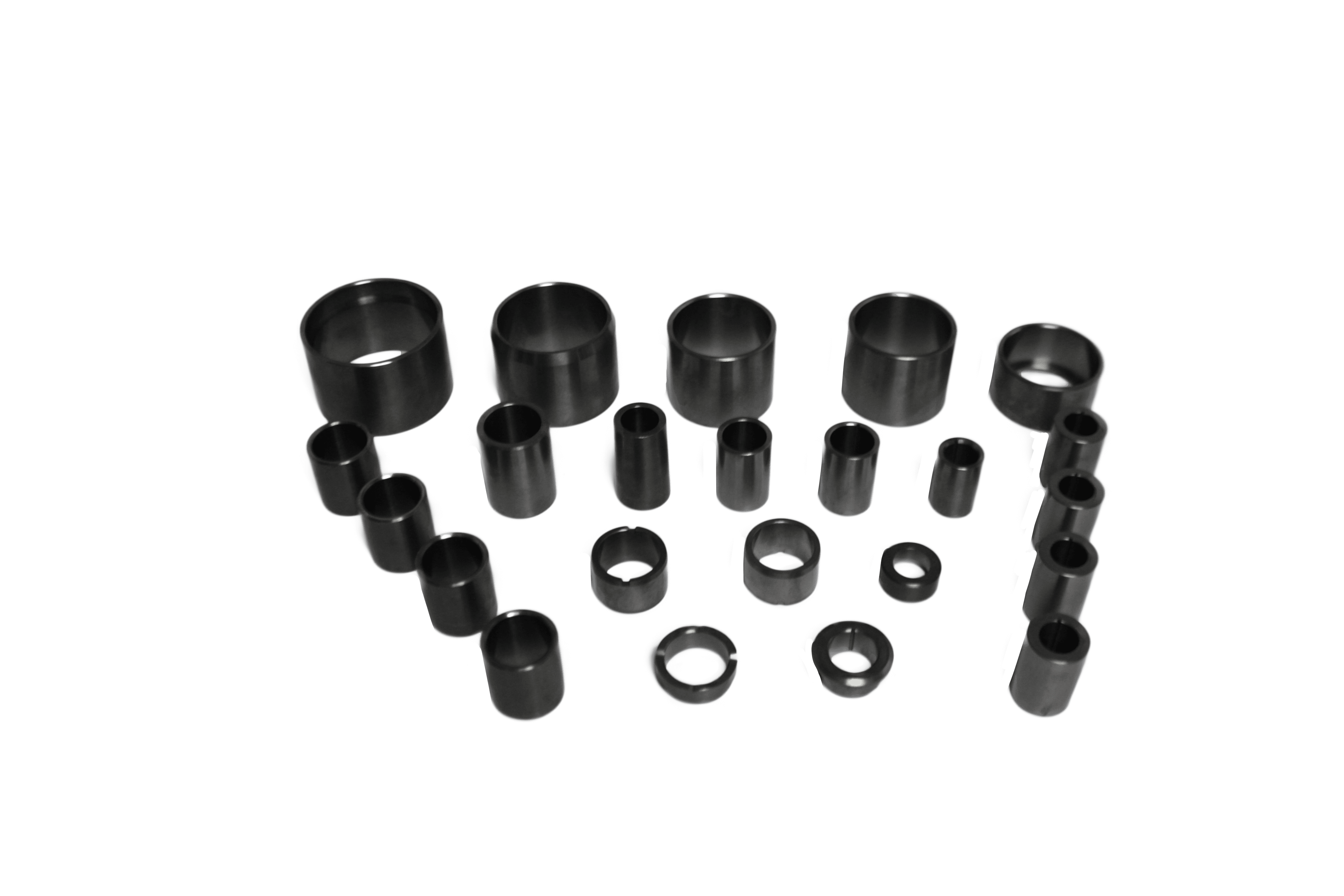

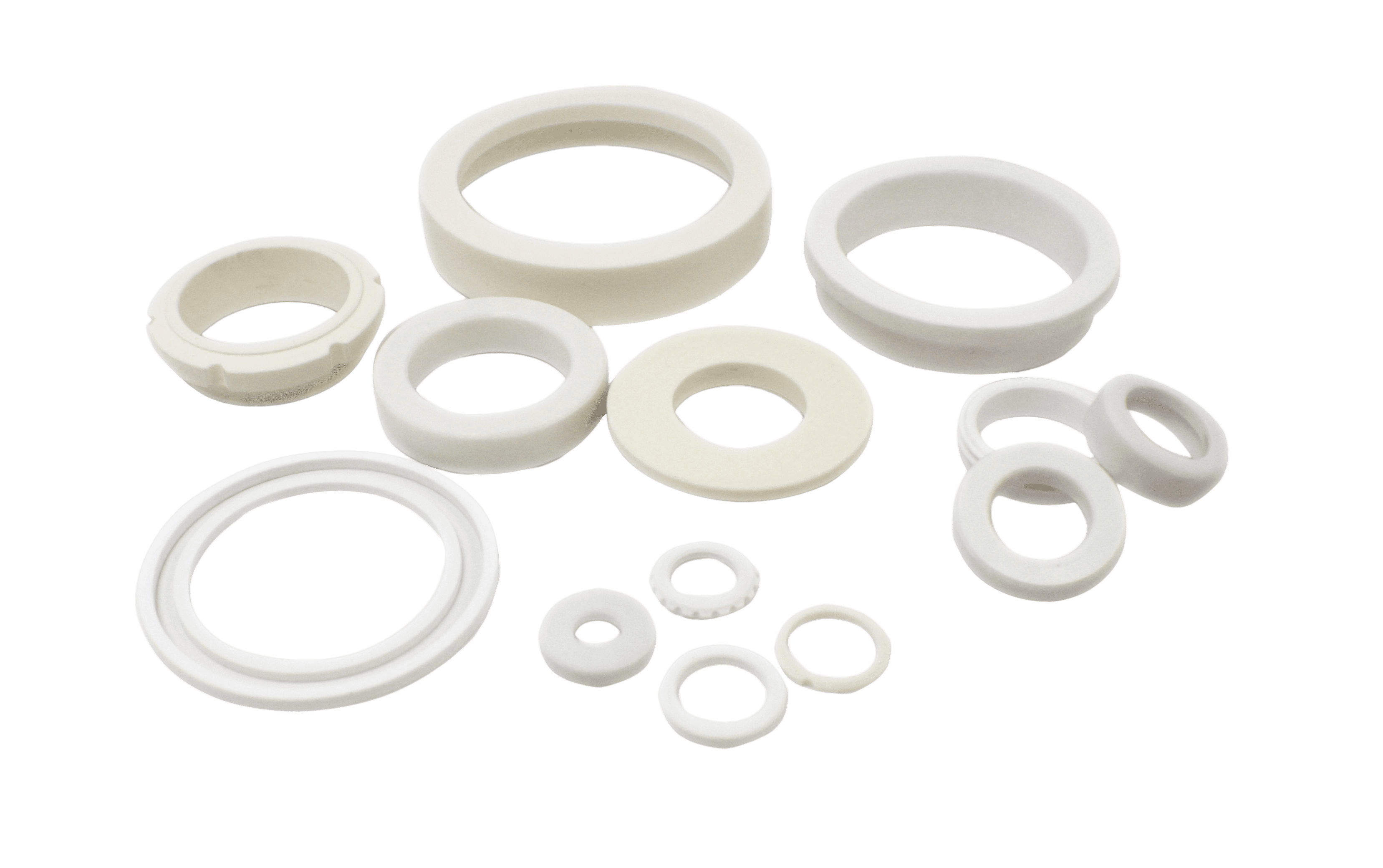

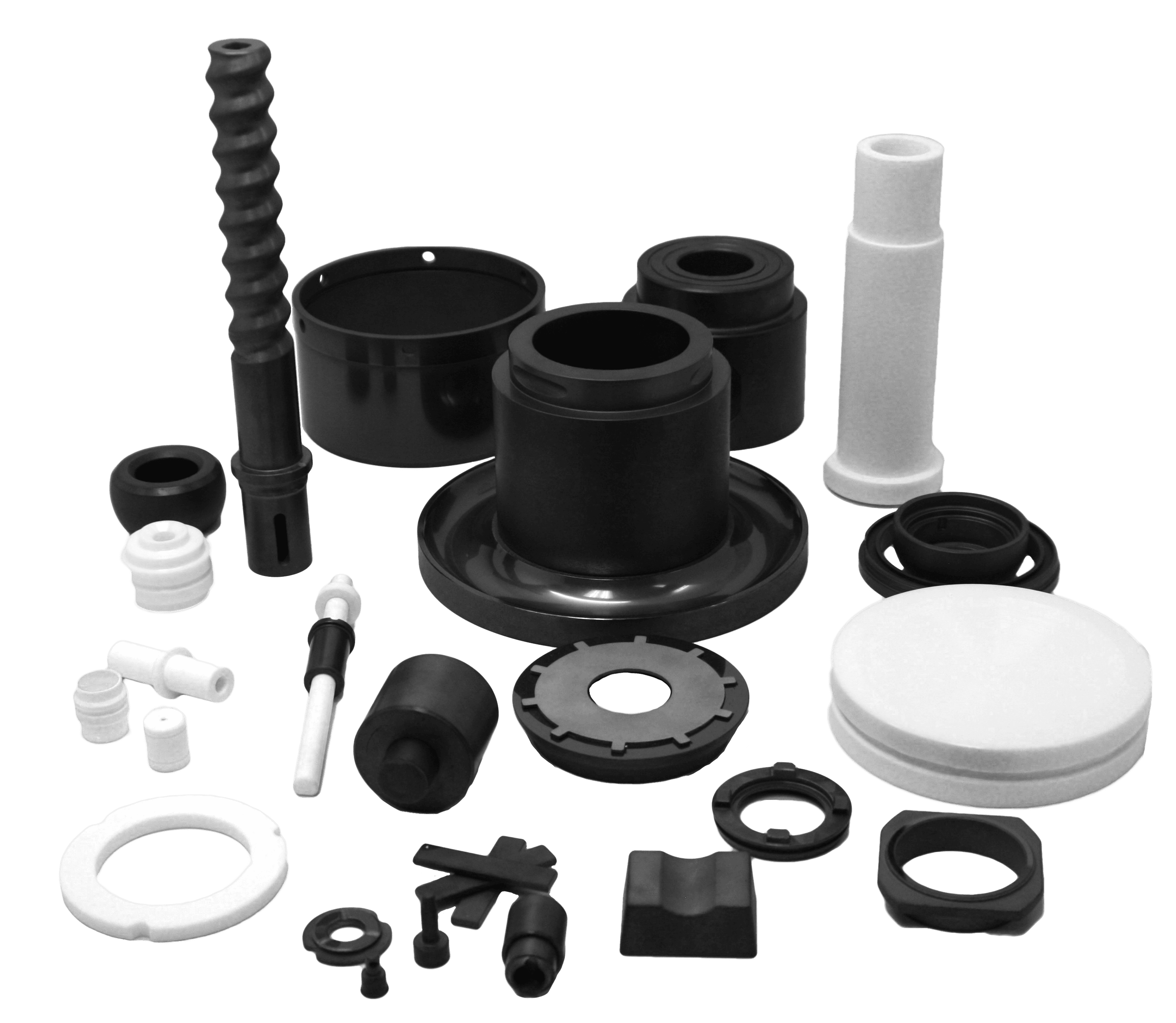

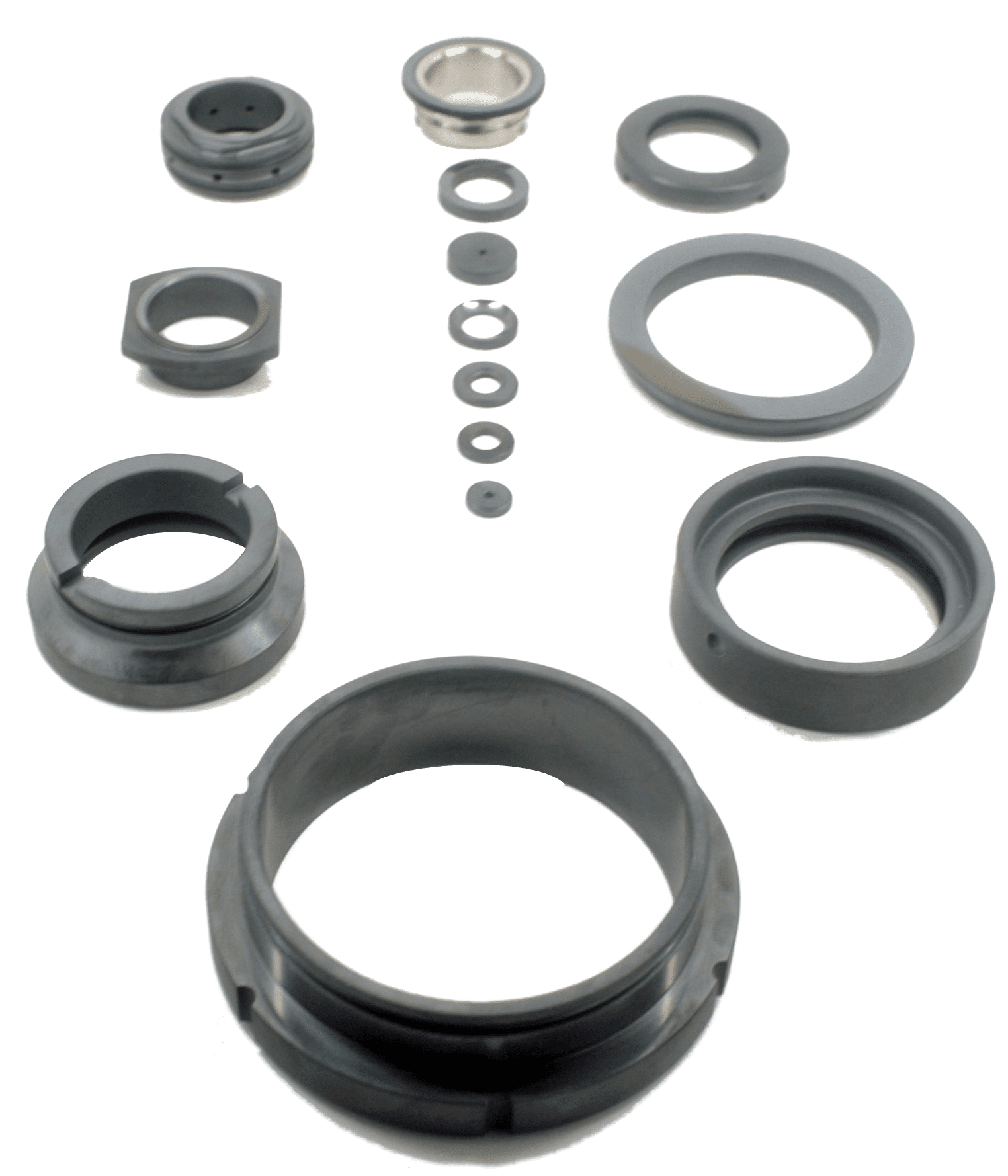

Seals

JJISCO offers seal components in custom and semi-standard designs to meet your size, shape, and hard material requirements. Our products aid in minimizing down time and increasing production. These seals will operate at temperatures up to 1500°C in corrosive, abrasive environments. Our experts ensure your components are comprised of the appropriate material to best meet your needs.

- Center Seals

- Custom Seals

- DIN Seals

- Double Face Seals

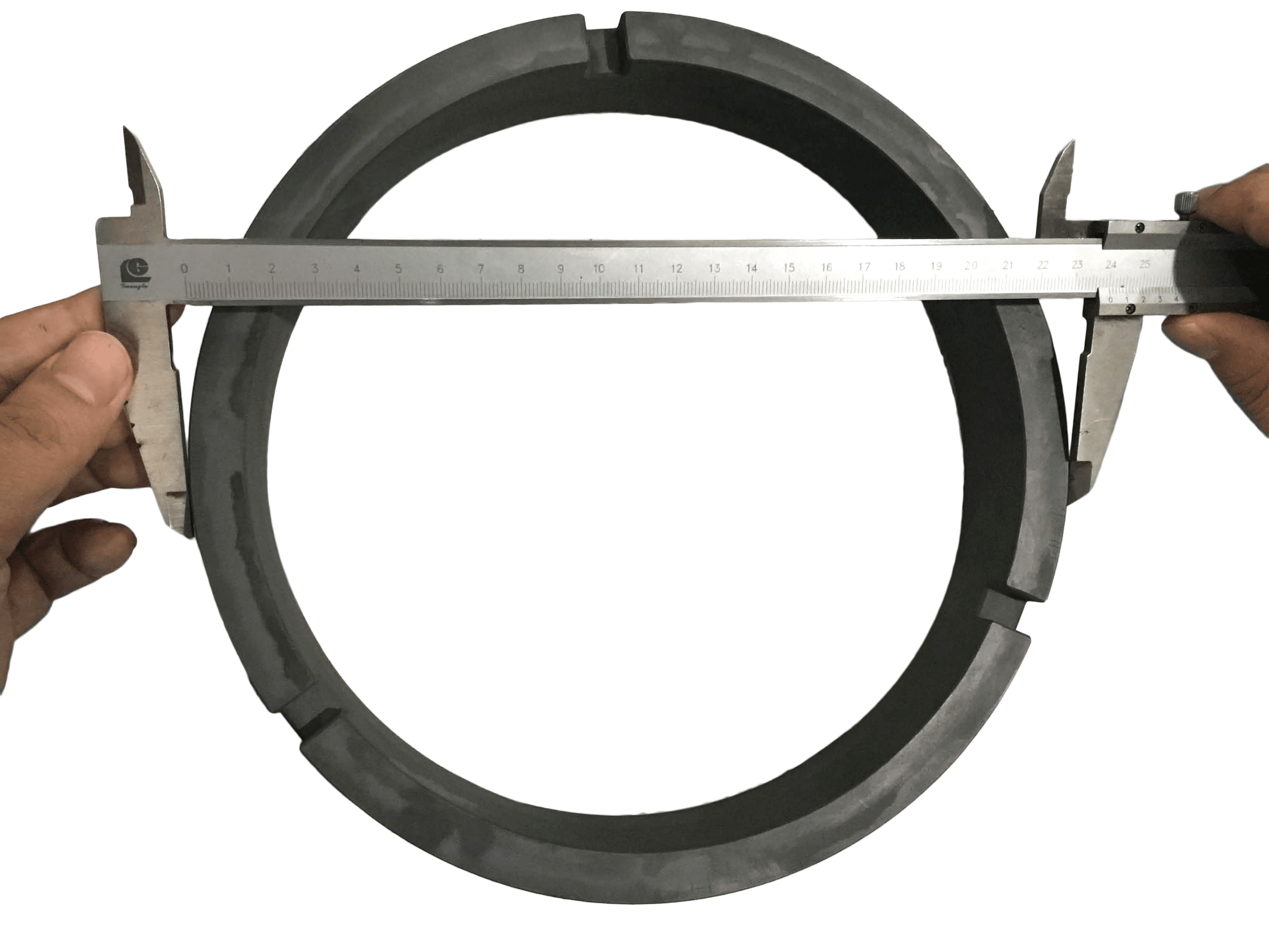

- Large Diameter Seal Faces

- Seats

- O-Ring Seals

We thrive on unique geometries, yet still welcome typical designs. Small diameter capabilities to 0.25” [6mm], and large diameter designs up to 27” [700mm] in silicon carbide and 18” [450mm] in tungsten carbide.

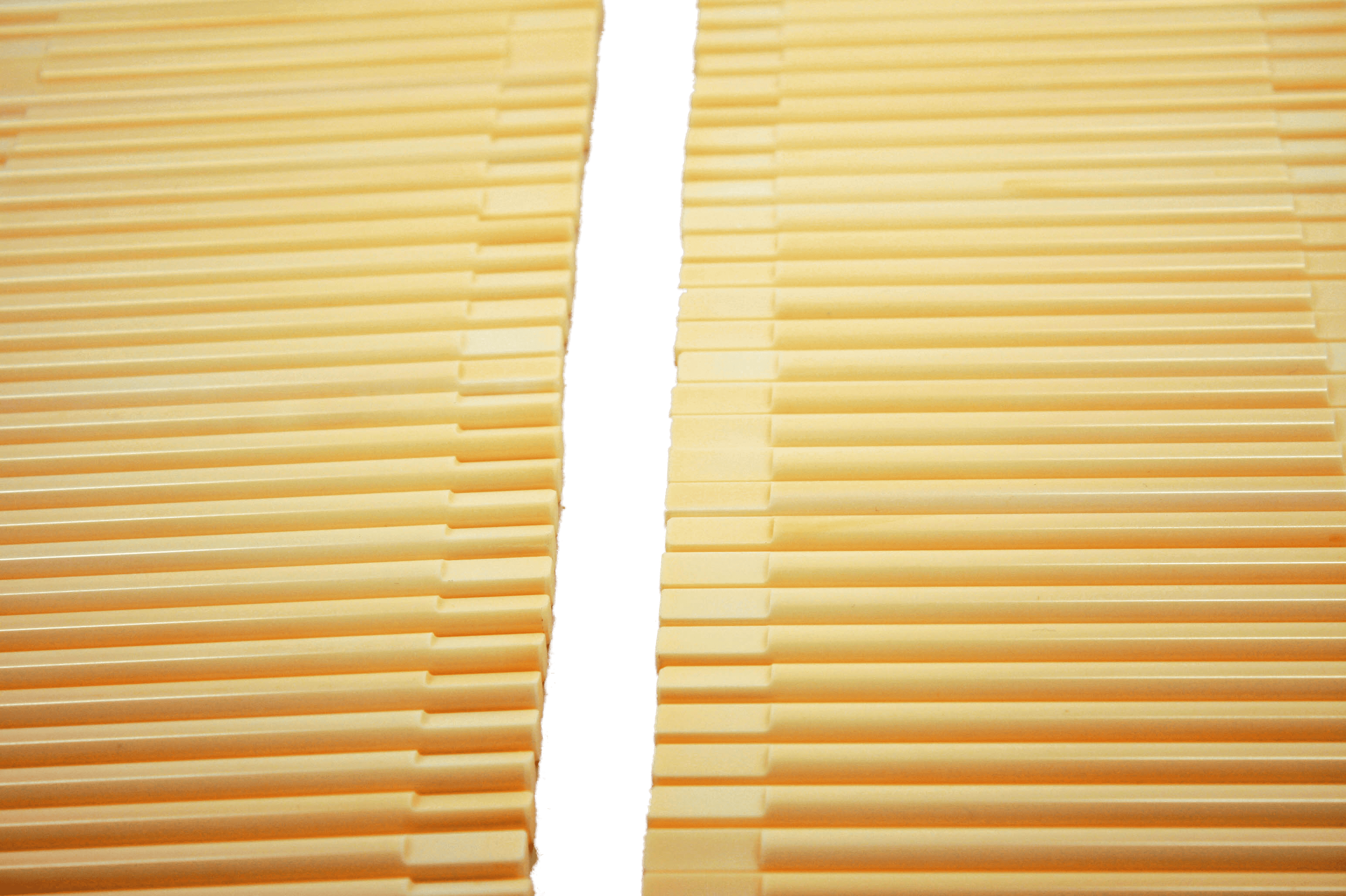

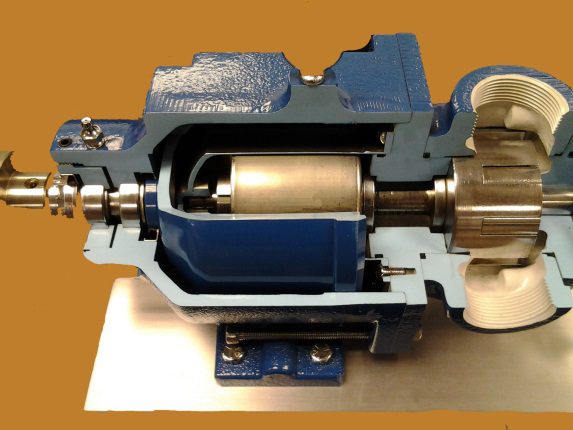

We provide axial designs, including seal faces in mechanical seals. We offer all types, standard and custom, as well as steam joint and valve seats. We also offer radial designs, including multi-segmented rings, shaft seals, gas seals, control rings, and seals for regulating devices.

In mechanical face and sealing applications, wear can occur due to diverse environmental conditions, abrasive media, slurries, and shaft deflections. This may ultimately cause a complete failure of the seal.

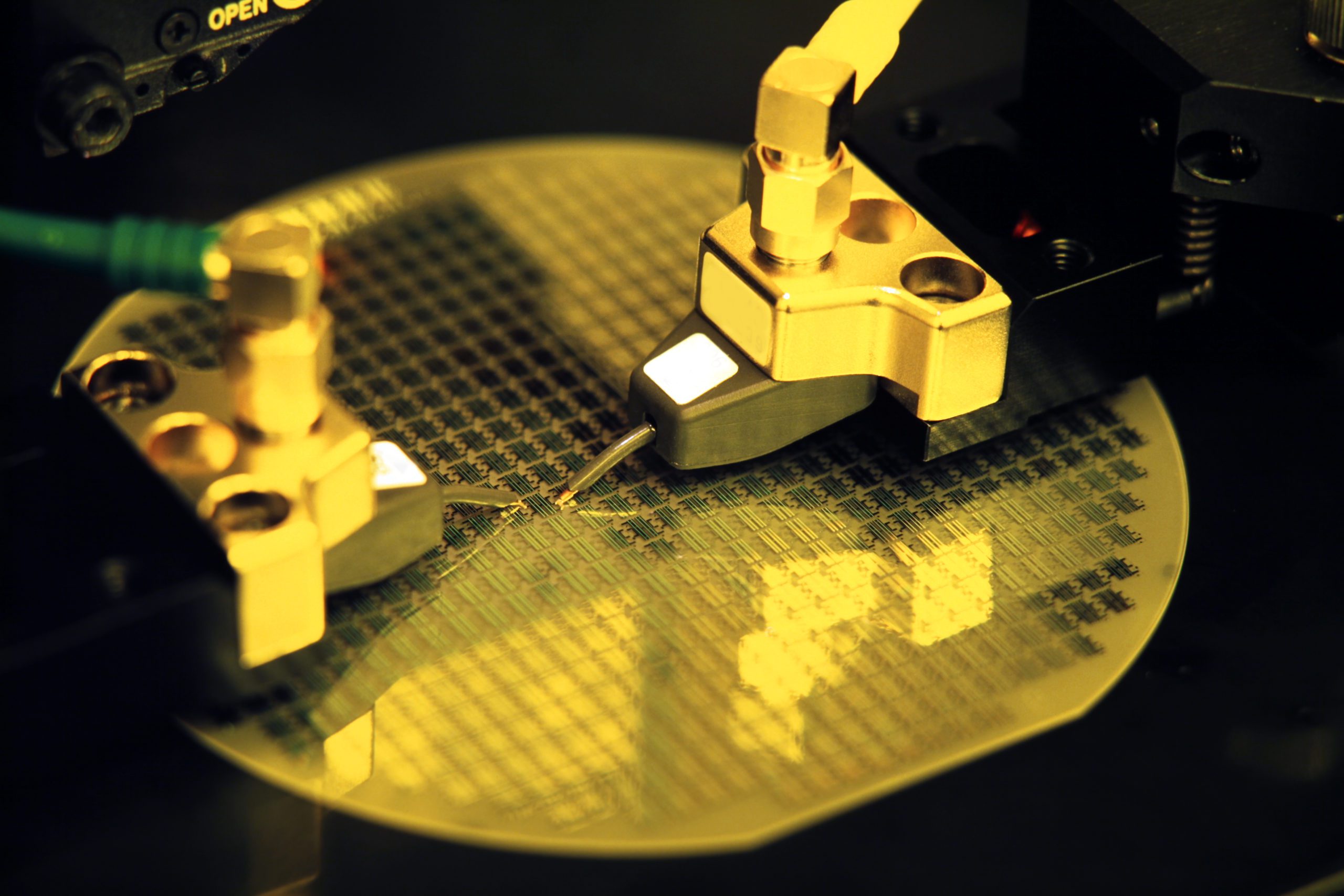

JJISCO offers the following material options to ensure our seals will meet your application needs:

- Silicon Carbide – JJISCO’s AlphaLAST® sintered silicon carbide is an extremely hard and wear-resistant material for the best chemical resistant applications.

- Tungsten Carbide – Our NiLAST® (WC-Ni) and BlackLAST® (WC-Co) tungsten carbide can withstand extreme wear, corrosion, impact, loading, and deformation.

- Aluminum Oxide (Alumina) – AlumaLAST® aluminum oxide offers superior chemical resistance where purity of materials is required. Under challenging environments, AlumaLAST offers an excellent combination of lower cost and long life.

Please contact us further for your specific application requirements.

Request a Brochure