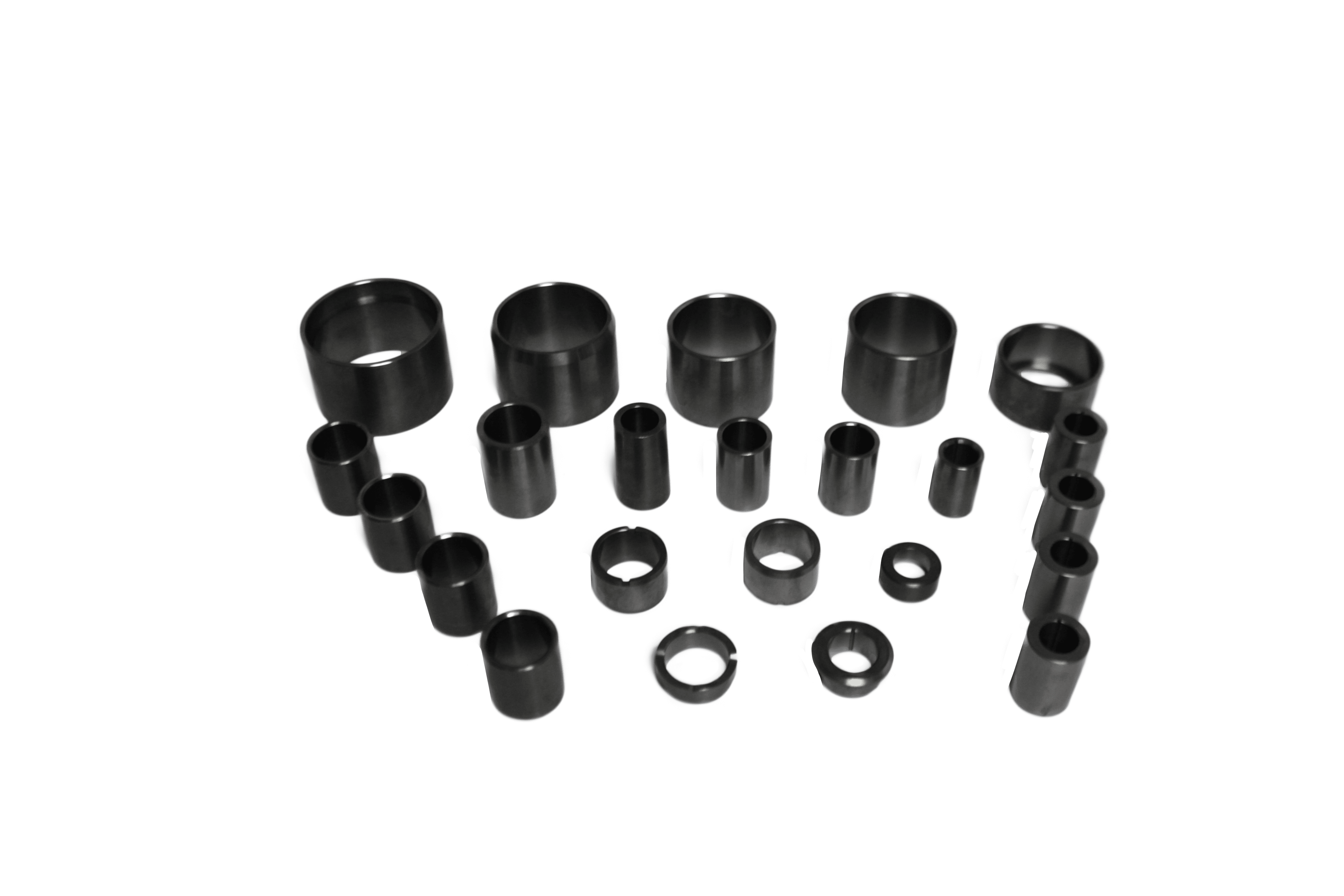

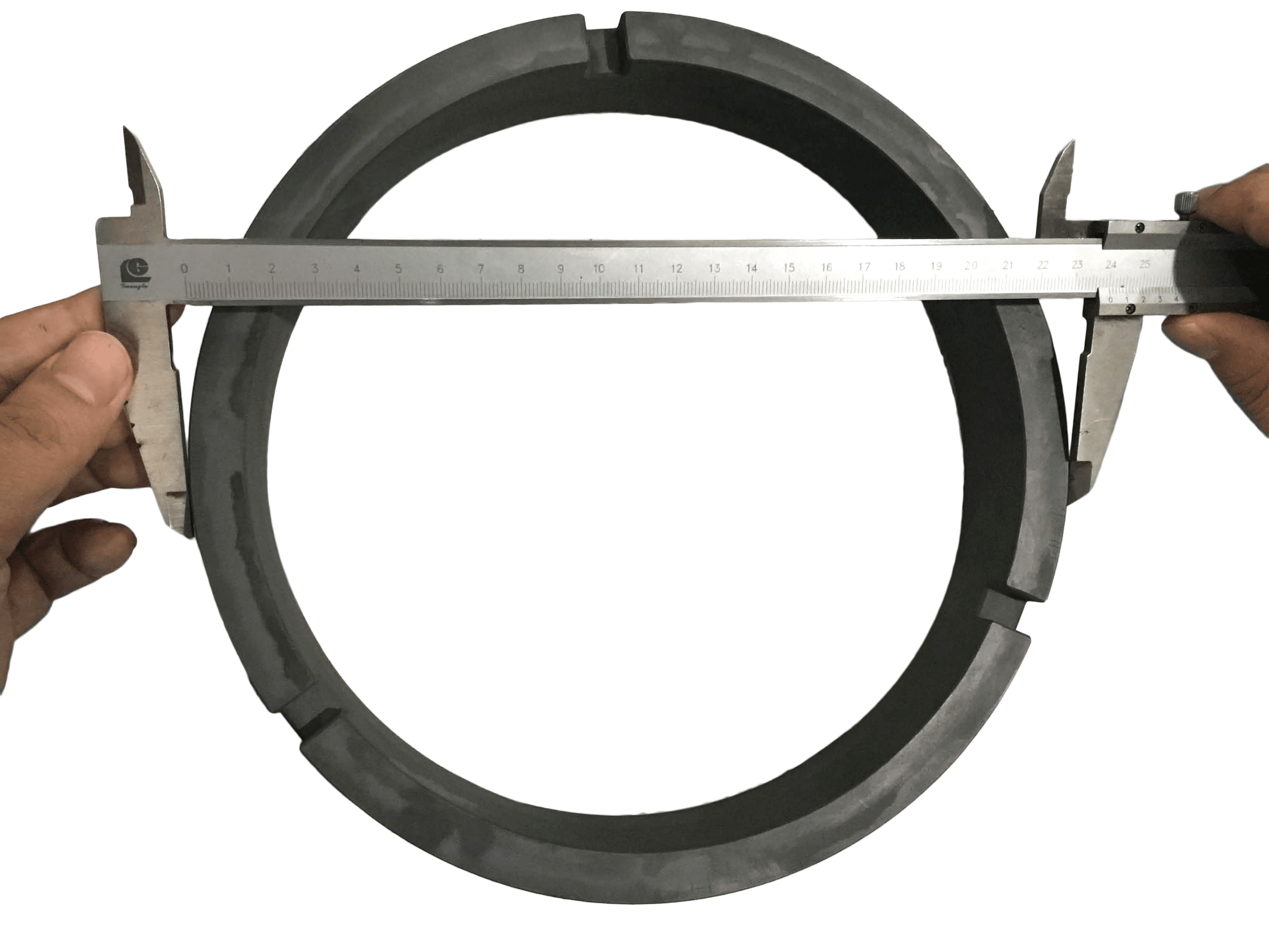

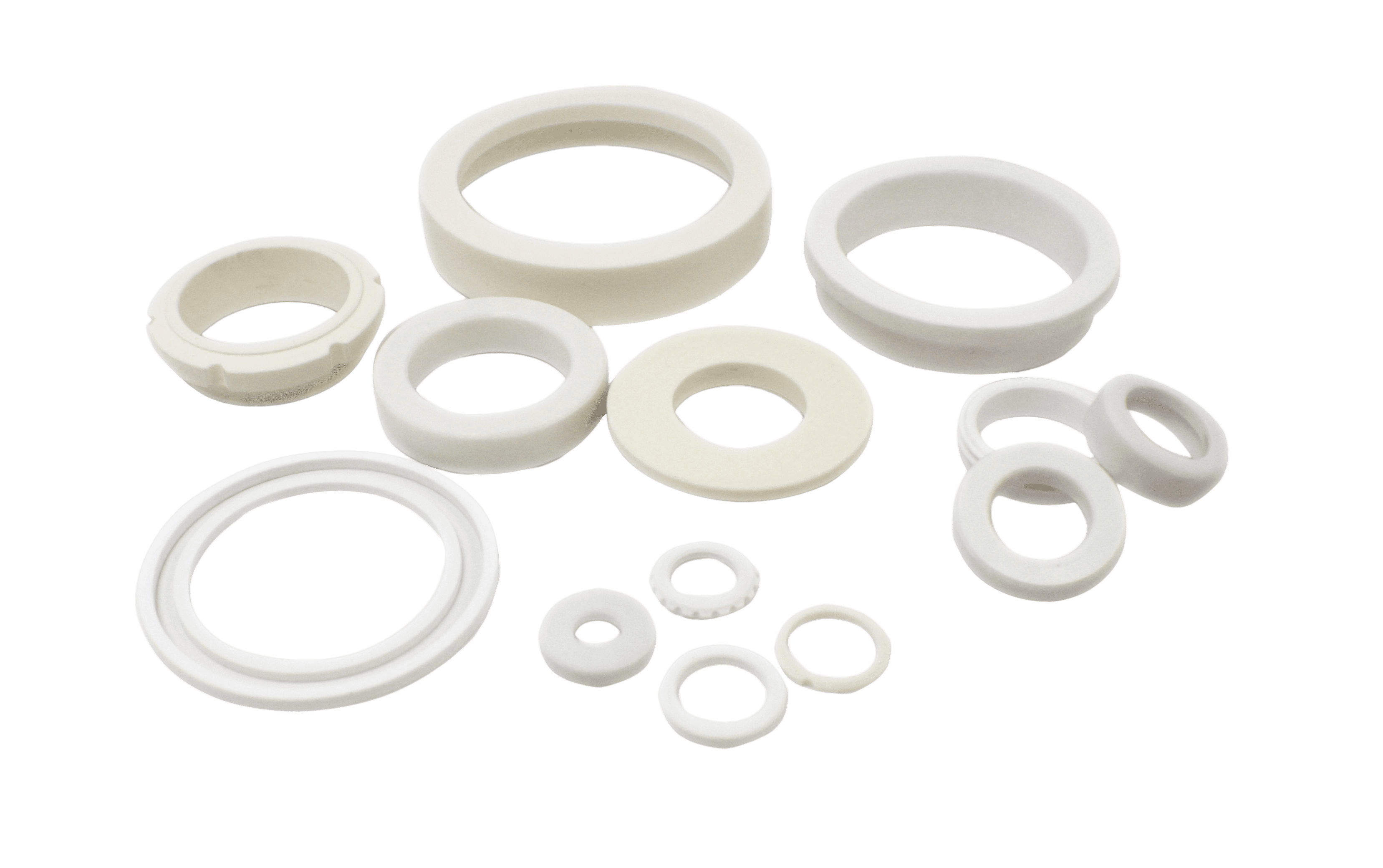

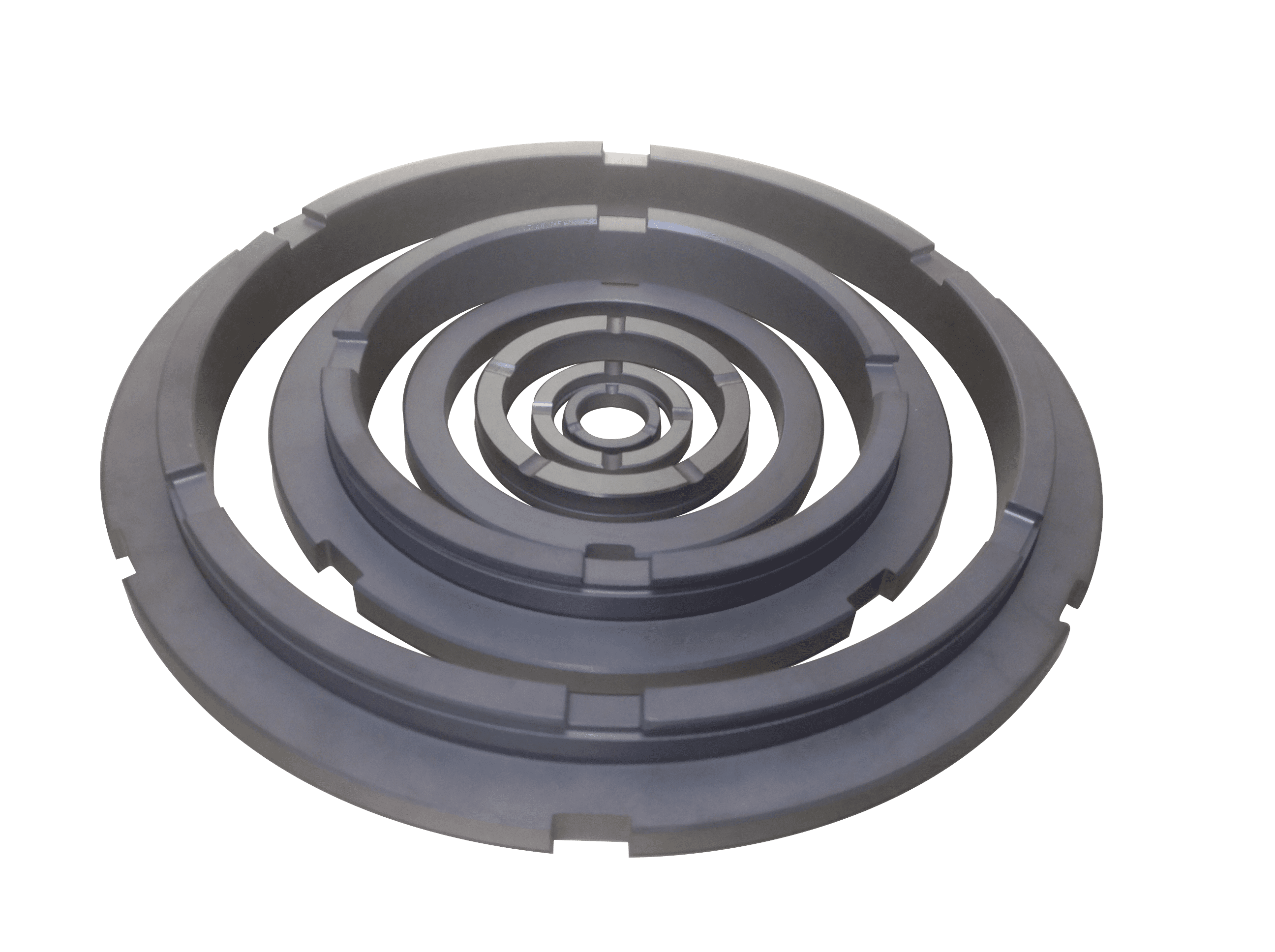

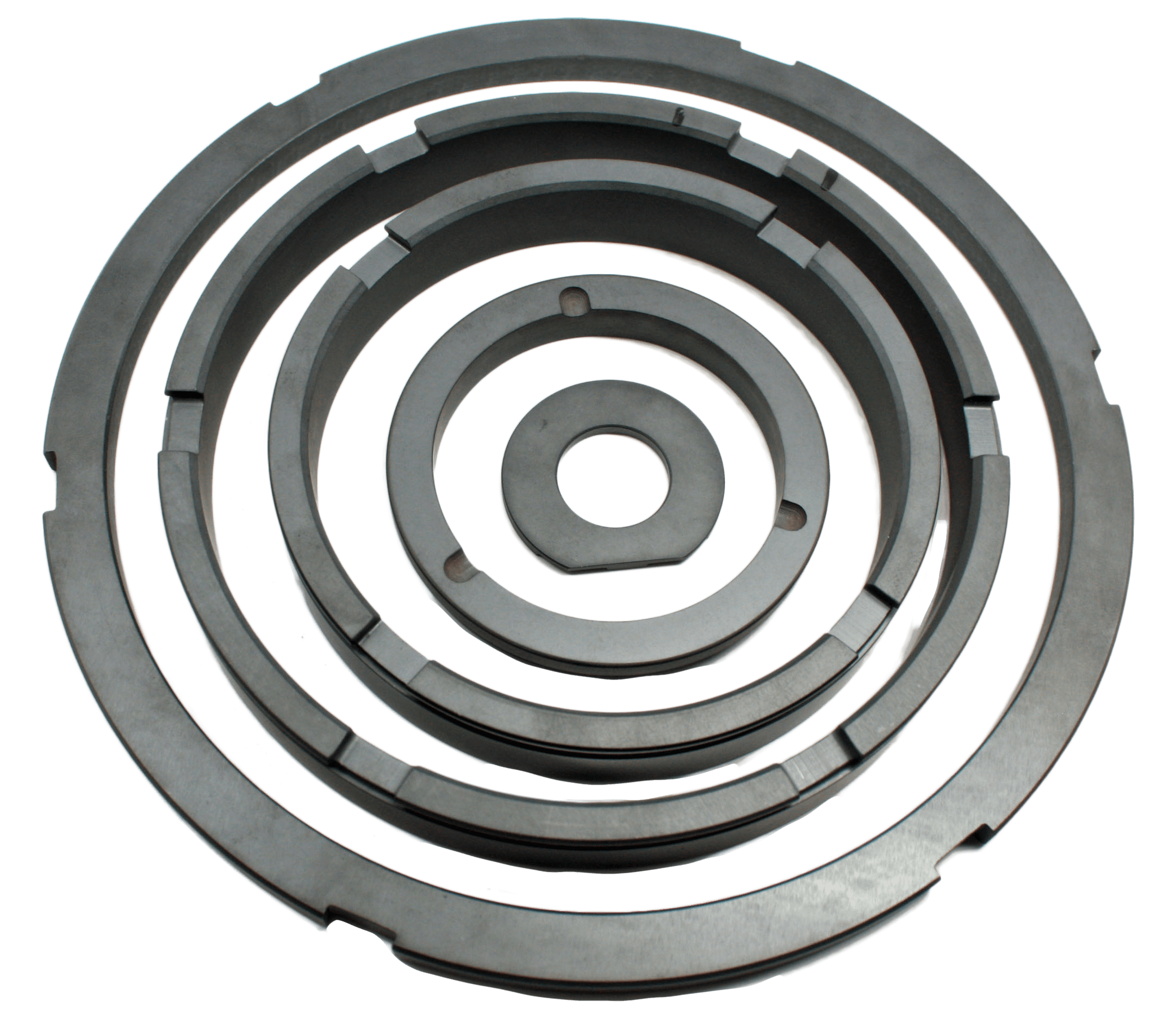

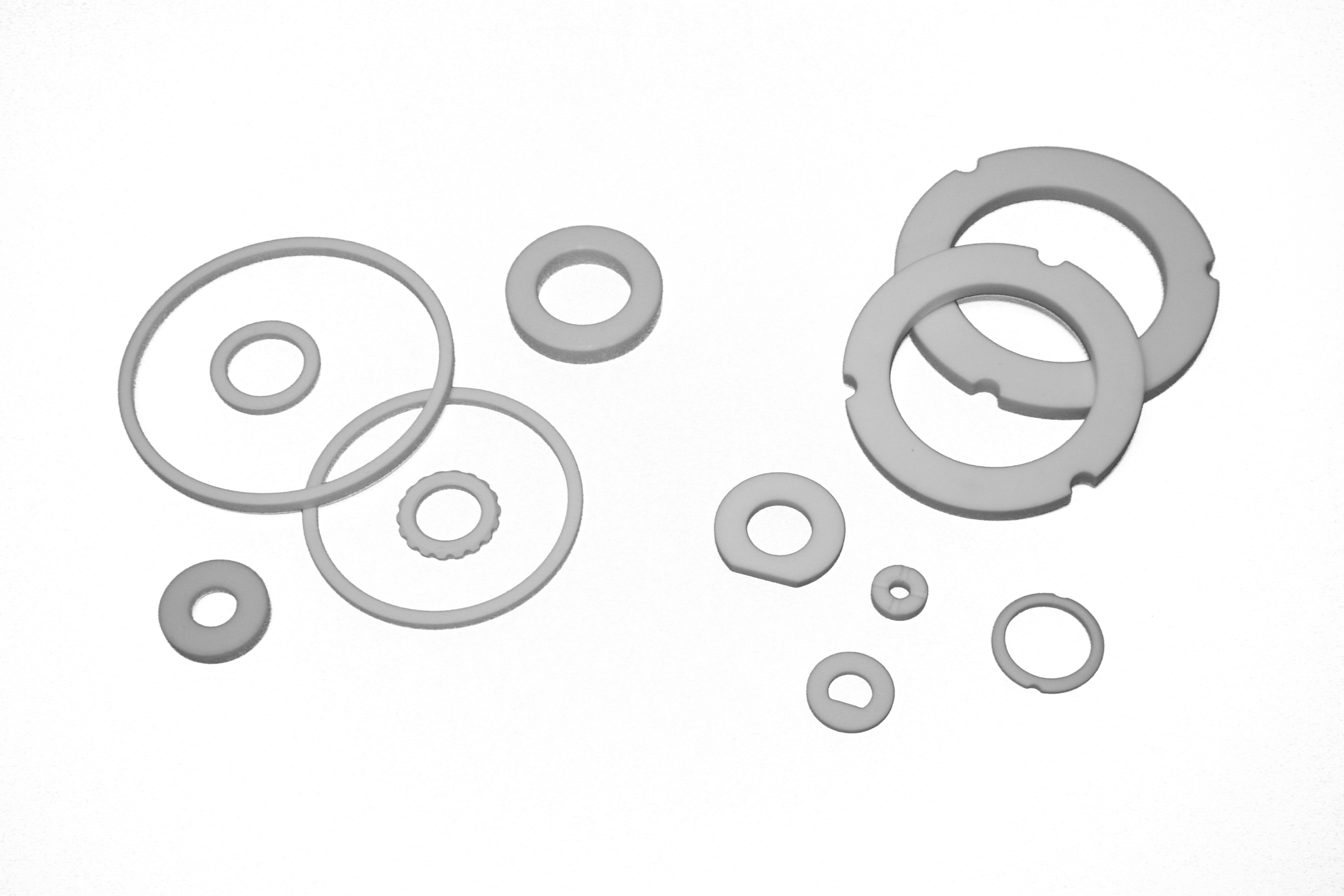

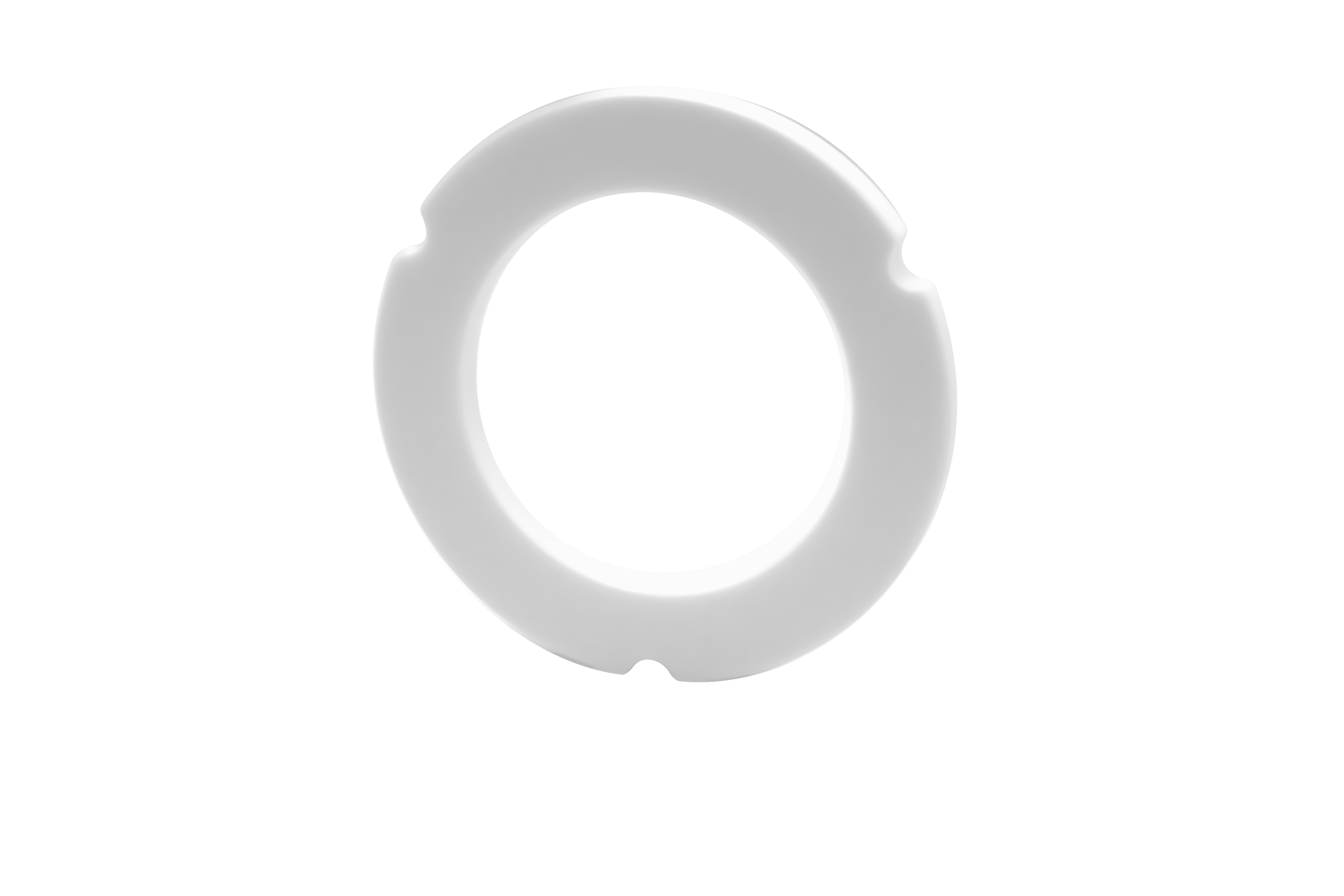

Wear Rings/Thrust Washers

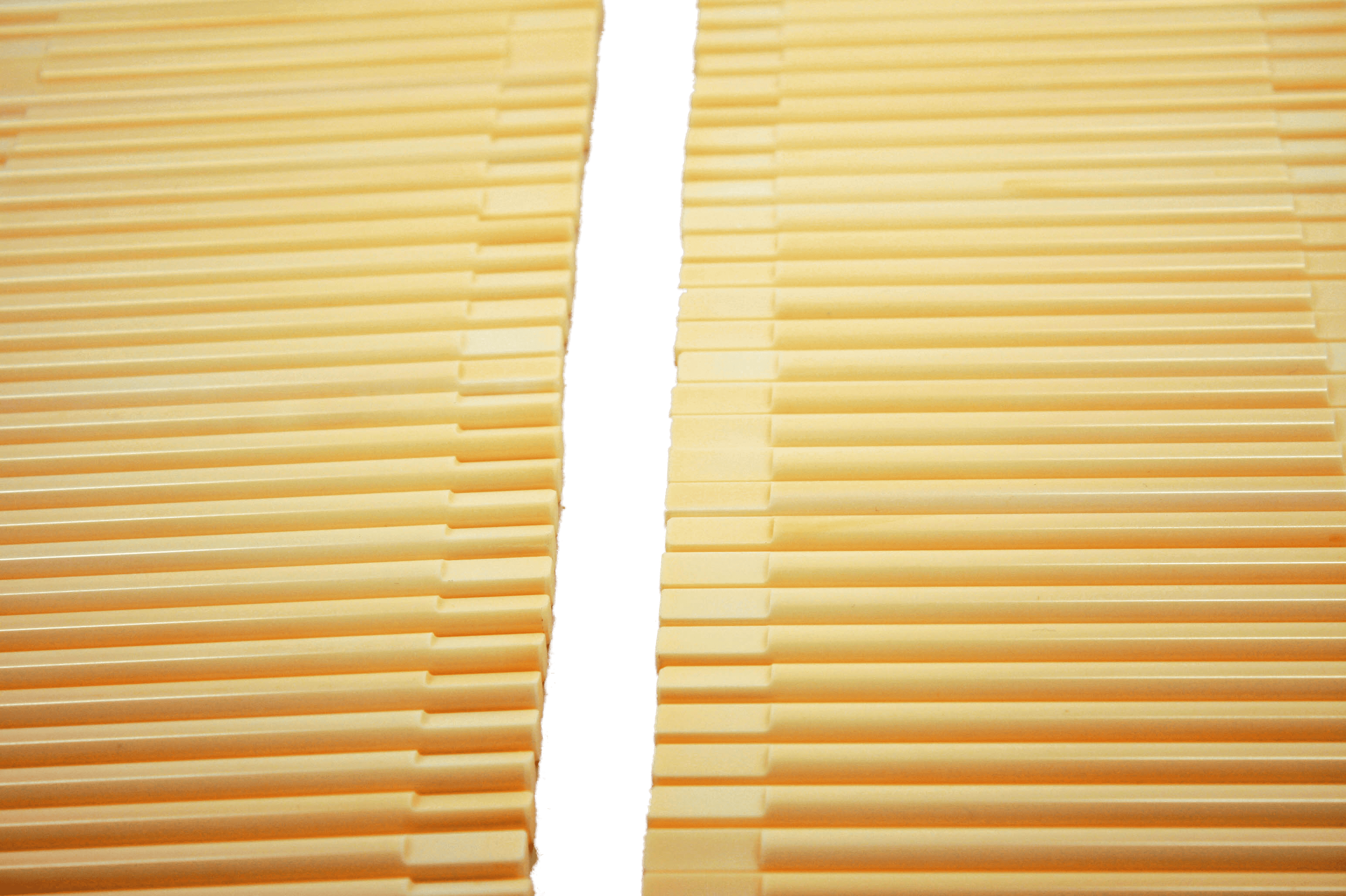

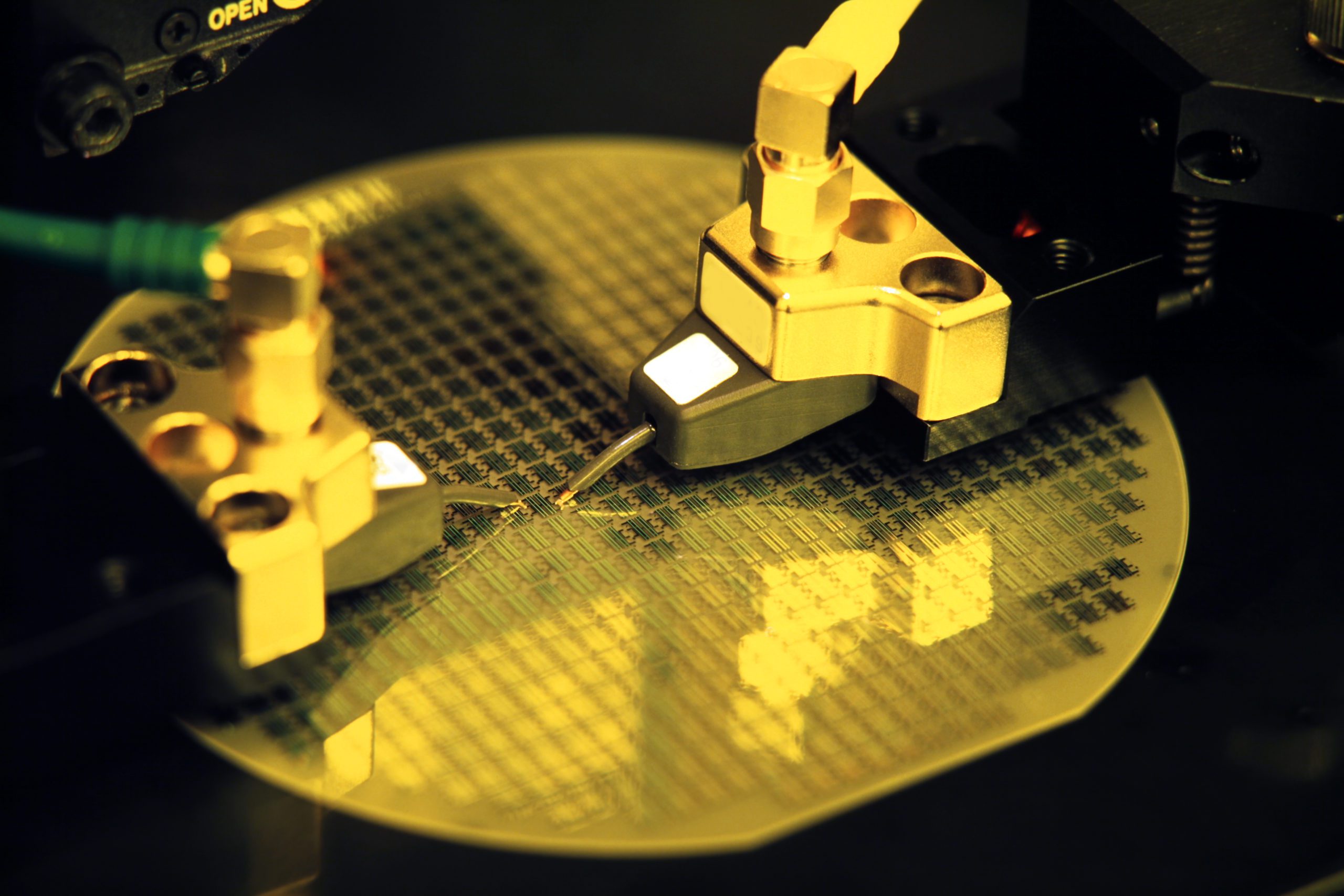

JJISCO offers wear ring and thrust washer components in custom and standard designs to meet your size, shape, and material requirements. Our engineered silicon carbide and ceramic materials will operate at temperatures up to 1900 F in corrosive or abrasive environments.

- Backup rings

- Shaft rings

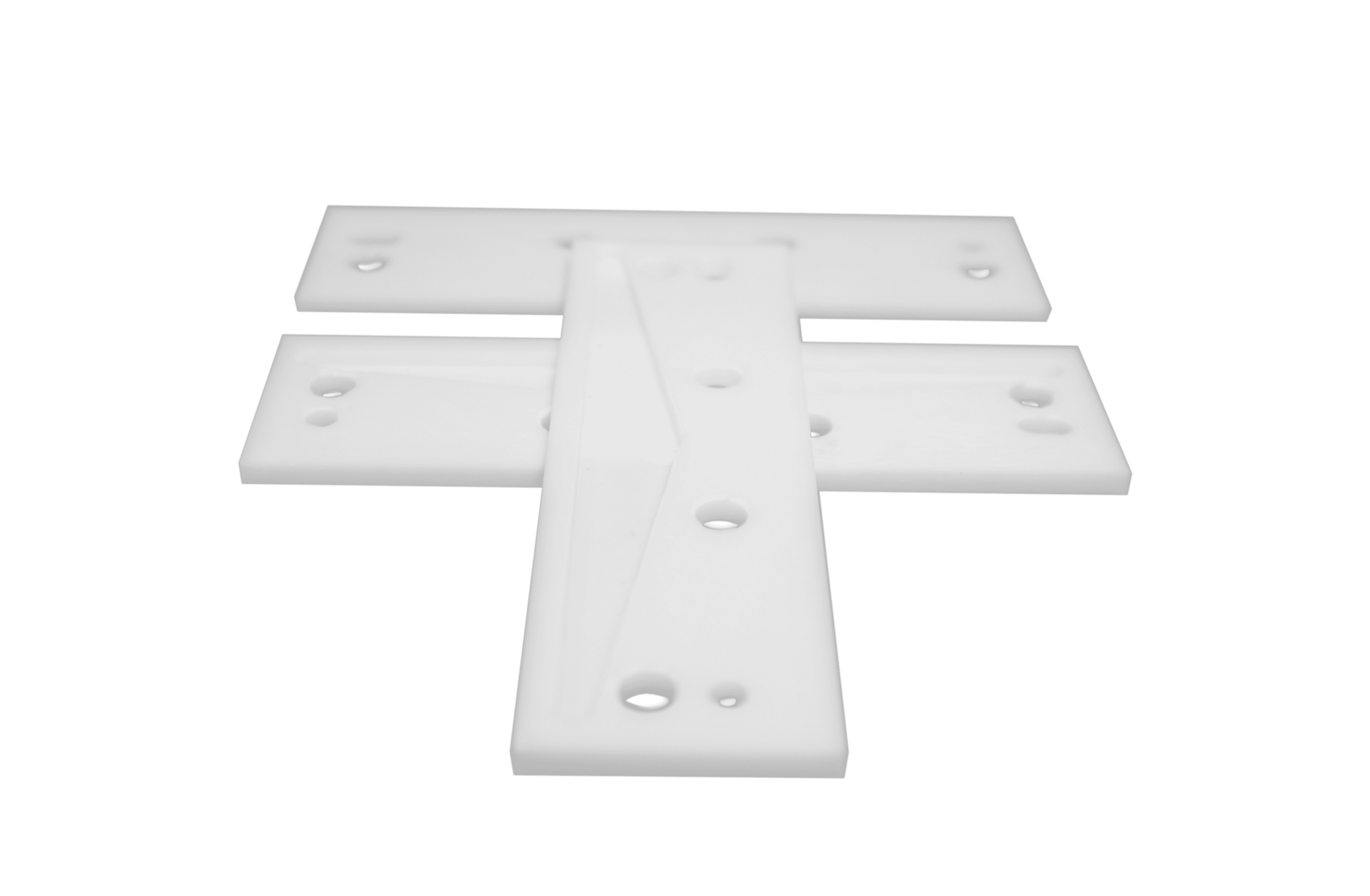

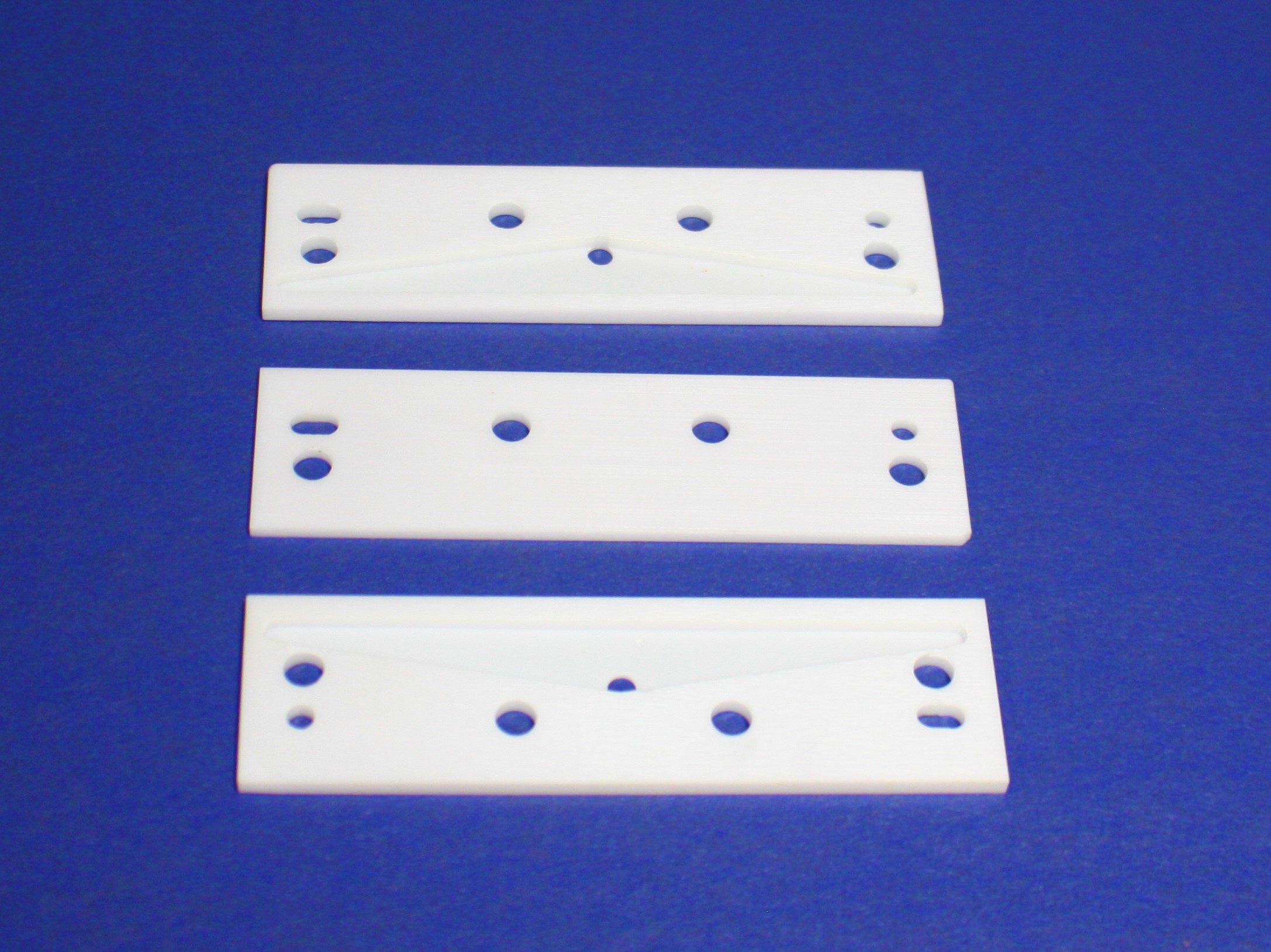

- Thrust washers

- Thrust pads

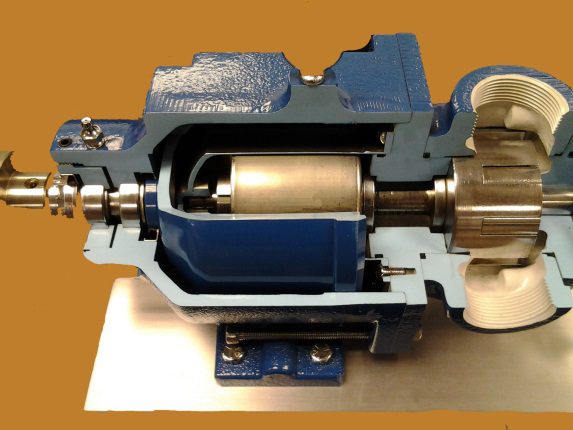

We have demonstrated proven success in a wide variety of applications and pump design types, including:

- Centrifugal pumps

- Magnetically-driven pumps/Mag drive

- Vane pumps

- Vertical pumps

- Down hole pumps

- Valve plates, washers, and seats

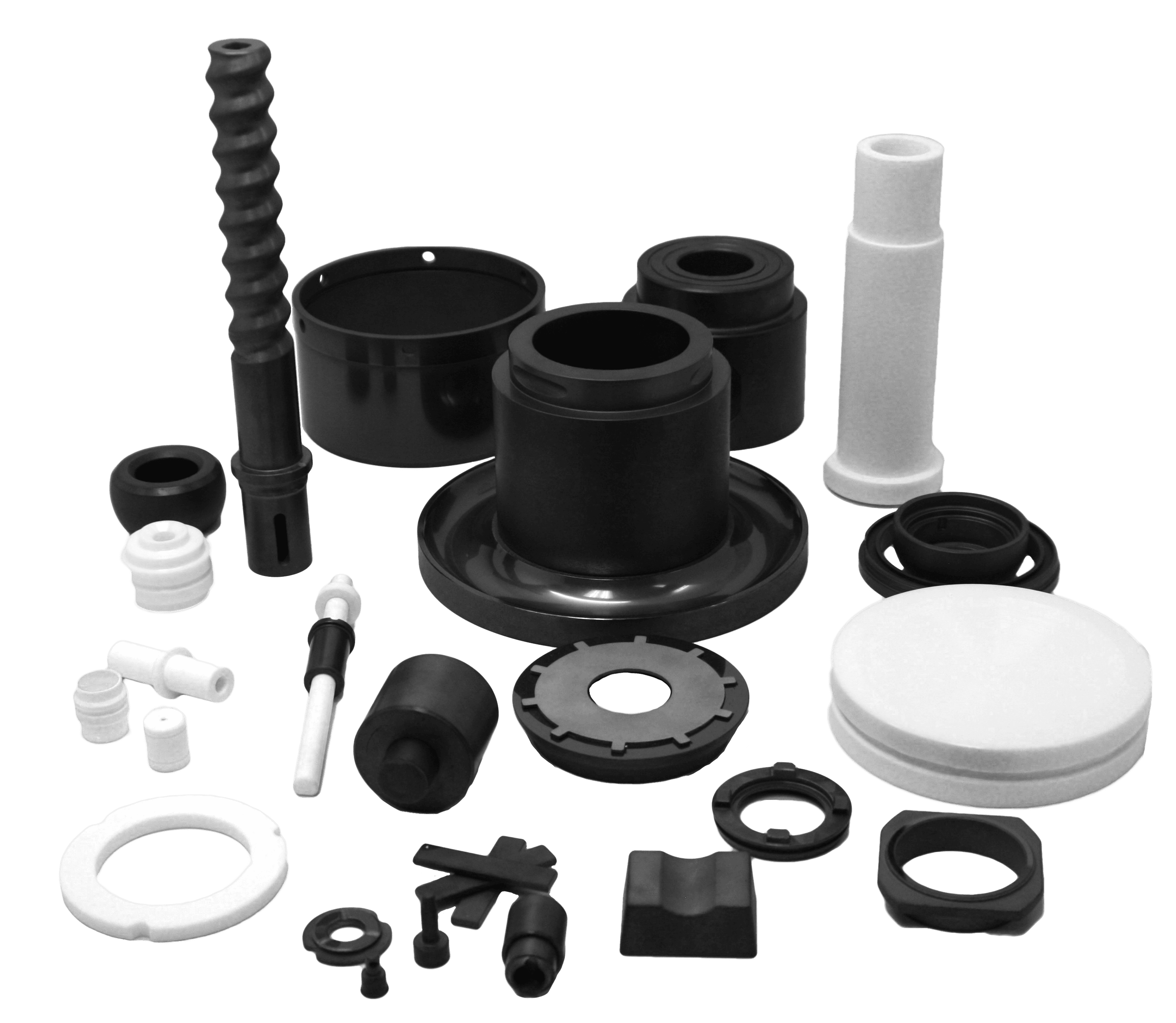

In severe applications, wear can occur due to abrasive media, chemical corrosion, and excessive force, and may ultimately cause a complete failure. JJISCO utilizes extremely hard and wear-resistant materials for radial and thrust loads. Key material characteristics include: superior hardness and high strength, high abrasion and wear resistance, and extreme corrosion resistance.

Based on your requirements, we offer multiple hard material options for the best cost-benefit solution.

- Silicon Carbide / AlphaLAST® and Extrema

- Tungsten Carbide / NiLAST® (WC-Ni) and BlackLAST® (WC-Co)

- Aluminum Oxide (Alumina) / AlumaLAST®

- Zirconium Oxide (Zirconia) / ZiaLAST®

Please contact us further for your specific application requirements.

Request a Brochure