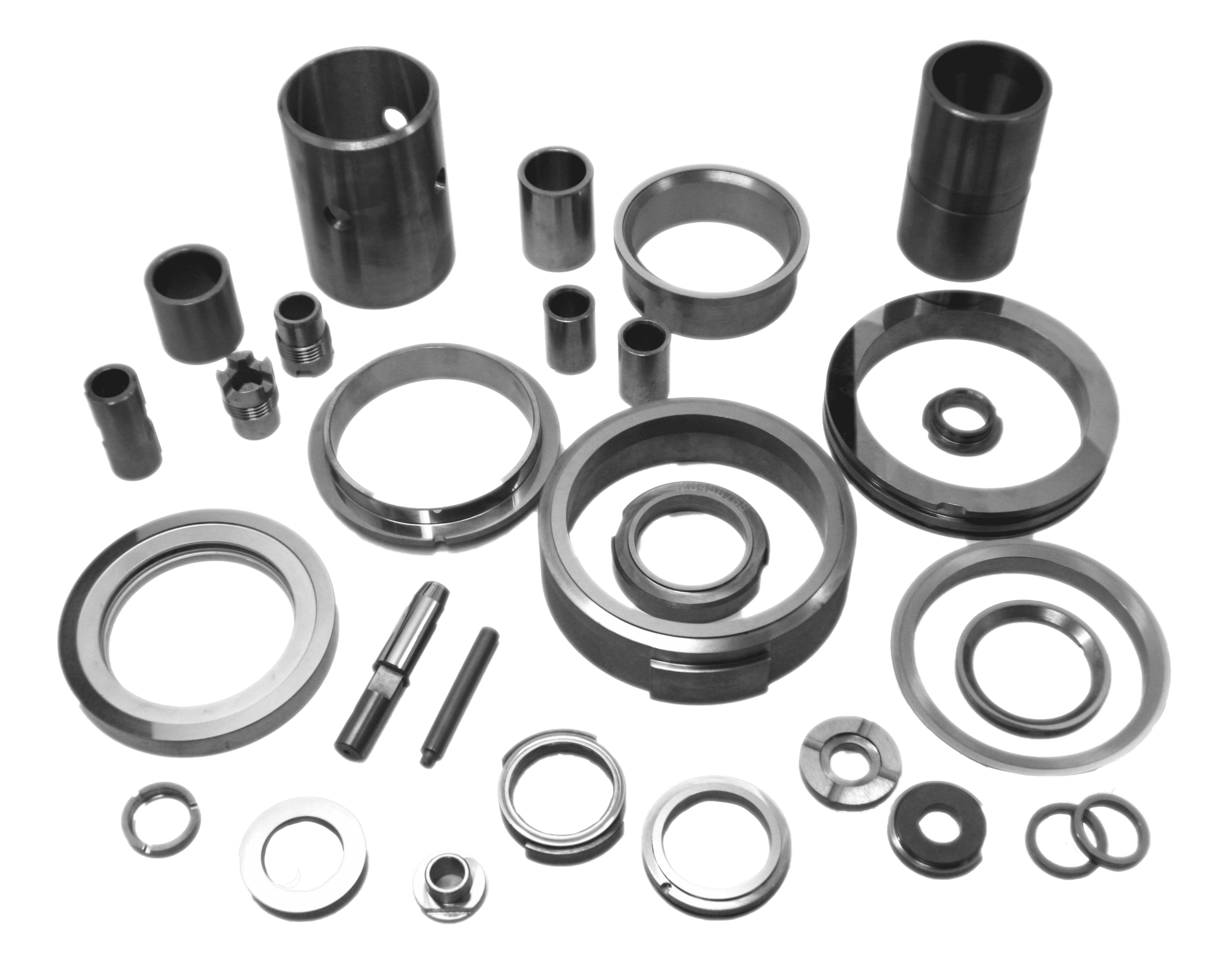

Tungsten Carbide

Tungsten carbide is one of the toughest, most reliable, and extremely durable metals you can find. No other metal compound offers the same attributes, and it is used across every major industry. WC components are often used for parts that must withstand extreme wear, temperature, corrosion, loading, and deformation.

It is resistant to heat, rust, scratches, and pitting. It also boasts an extremely high density, with a hardness just below diamond, ranking about 9 on the Mohs scale, and a Vickers number of approximately 2600. It offers excellent conductivity and provides three times that of steel equivalents.

Easily molded into many shapes for mechanical and wear application requirements, it is ideal for countless high pressure industrial applications due to a high modulus of elasticity which helps prevent face distortion.

Tungsten carbide parts are typically comprised of a cemented carbide (or hardmetals), induvial WC grains imbedded in a metal binder matrix of either cobalt or nickel. The toughness and hardness properties can conform to specific application requirements by adjusting the grain size of the tungsten carbide and/or the binder content.

JJISCO offers both nickel and cobalt-binder tungsten carbide products, and our Family of LASTing Brands includes:

- NiLAST® 4-15% Nickel Binder Tungsten Carbide

- BlackLAST® 4-15% Cobalt Binder Tungsten Carbide

Submicron, fine, medium, and coarse grains are available for your specific application.

Request a Quote

Upload a drawing for engineering review or to ask design/material questions

Request a Material Data Sheet

Contact us for more detailed information on your preferred material